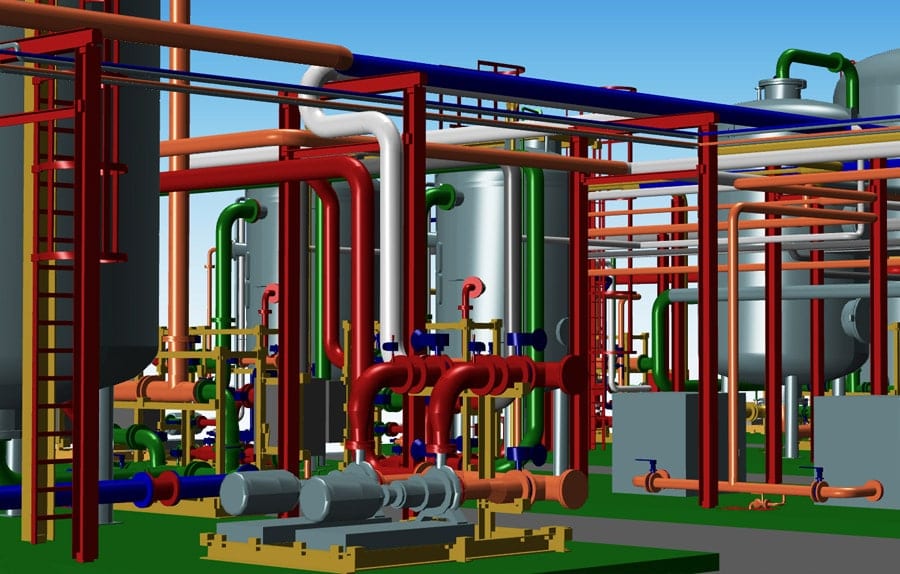

Get best piping design and drafting services, 3D modelling, pipe stress analysis, equipment layout, pipe sizing etc. Our piping systems work well in automobiles, industries, locomotives, marine vessels from the circulation system. The piping system helps in space reduction for setup, enhanced safety, increased accessibility and easier maintenance. It’s used to visualize piping layouts, CAD tools, and other installation for a specific purpose. Our team of engineers, specialists, and experts bring value from 2D to 3D pipe layout to ensure safety, liability and simulate piping system scenarios.

With years of experience in architectural design, our project manager uses a wide range of design services for both small to large manufacturing companies. We use the best piping system using the desired operation of plants to different loads stresses like temperature, pressure and other seismic conditions. Our AutoCAD drafting & design engineers can handle different specifications, standards for creating layouts for complex plants, creation of layouts for large structures, equipment, building etc. We as one of the drafting companies, our home designers use 3D CAD drawings a design process at an affordable price.

nd

nd

Pipe Stress Analysis Services

Our piping system is subject to extreme pressure conditions and temperature. We offer stress analysis, piping, flexibility readings for industries within a good turnaround time to ensure reliability, safety and stimulate the worst-case system scenarios.

Our Piping Systems and Pipe Stress Analysis Services Include –

- Piping systems – CAD

- Paper or blueprint to CAD

- 2D piping layouts

- 3D Piping layouts

- Conceptual Pipe Routing

- Plot plan Development

- Pipe Sizing Calculation

- Piping Design Criteria Development

Pipe Stress Analysis carry out on the following types:

- Nonmetallic (Example: FRP (GRP), HDPE, PVC, etc.)

- Metallic

- Buried

- Sub Sea

- Internally Lined Piping (Ex: Ceramic Lined Pulverized Coal Piping)

- Jacketed

- Cross Country Pipelines

- All loads (Weight, Thermal, Seismic, Wind, etc.)

Australian Design & Drafting Services team has been providing Piping Systems and Piping Stress Analysis for Industries Like –

- Process industries

- Oil and gas

- Petrochemicals

- Offshore platforms

- Fertilizers

- Food and beverages

- Refrigeration plants

- Marine vessels

- Power

- Industrial installations

Piping Design and Drafting Services for industries

Here are some key aspects of piping design and drafting services:

- Process and Instrumentation Diagram (P&ID) Development: P&ID is a schematic representation of the piping system that shows the interconnection of process equipment, control instruments, and the flow of fluids within the system. Piping designers create and update P&IDs to document the entire process.

- 3D Modeling and Layout Design: Piping designers use advanced software tools to create 3D models of the piping system, including equipment, valves, fittings, and supports. This enables them to visualize the layout in a virtual environment and identify potential clashes or interferences.

- Materials Selection: Based on the nature of the fluid or gas being transported, the designers select appropriate materials for pipes, valves, and fittings to ensure compatibility, corrosion resistance, and overall system integrity.

- Stress Analysis and Pipe Support Design: Piping designers perform stress analysis to determine the structural integrity of the piping system under different operating conditions. They also design and specify pipe supports to ensure the system remains stable and can withstand thermal expansion and contraction.

- Isometric Drawings: Isometric drawings are detailed representations of individual piping components that provide information about dimensions, orientation, and connections. These drawings are essential for construction and installation.

- Compliance and Safety: Piping design and drafting services ensure that the piping systems adhere to industry standards, codes, and regulations, ensuring the safety of the personnel and the environment.

- As-Built Drawings: After the construction phase is completed, as-built drawings are created to reflect any changes made during the construction process, providing an accurate record of the final piping system.

When seeking piping design and drafting services, industries often rely on specialized engineering firms or consultants with expertise in this field. These firms employ skilled piping engineers, designers, and drafters who work together to create efficient, cost-effective, and safe piping solutions tailored to the specific needs of each industry.