Downstream Applications for 3D Data

What to do with a 3D model? Practically anything! Today, in this world that’s increasingly digital, most industries now utilize 3D files in some fashion. It shows up in many different places lately.

At this point, you have your 3D model from your scanned original part. It modelled digitally into a polygon format with reverse-engineered CAD format. Based on your needs, one can do things like adding 3D data that might thought of yet with covering different downstream applications used for 3D data file.

Downstream applications fall into the followings categories:

- Re-Engineering/Design

- Documentation/Archival

- Industry-specific Applications

- Visualization/Animation

- Inspection/Analysis

- Replication/Reproduction

DOCUMENTATION/ARCHIVAL

As your part or object, the laser scanned and modelled adding digital “backup” of the object. Scan data for archival purposes mainly used for a number of industries covering Aerospace, Consumer Products, Architecture and Museum/Fine Art. We at Australian Design and Drafting services, offer scanned objects that specifically used for the purpose of creating a digital document.

The digital model mainly used for:

- Protecting accidental part loss, used for almost insurance policy.

- It provides you working with “virtual” blueprint in order to recreate, rebuild, or remanufacture.

- It gives ability to start from a base model with creating something new without requiring to start from scratch.

RE-ENGINEERING/DESIGN

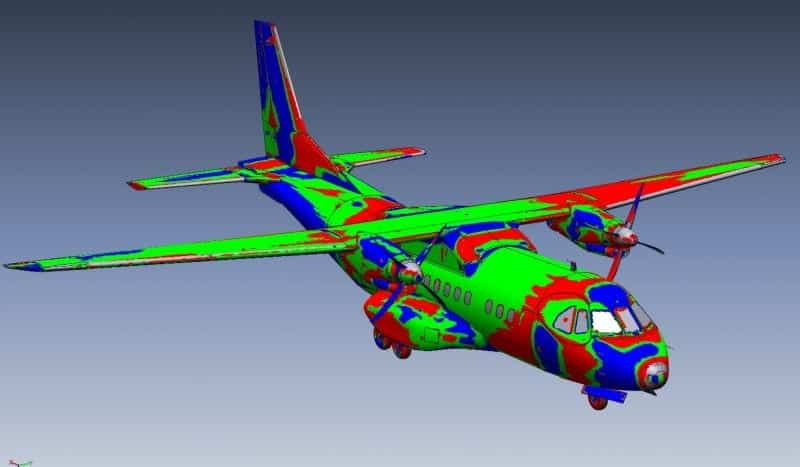

The Reverse Engineering process used as an application that mainly work as Aerospace/Defence and Industrial Design industries. With using a Reverse Engineered model, one makes engineering and design changes in object adding a variety of ways and use it for specific types of analysis including:

- Use various model for FEA and similar analyses

- Add or subtract design features into current existing part or object

- It uses base model to design new piece or object.

INSPECTION/ANALYSIS

It uses process, adding inspection 3D data particularly for any types of manufacturing. Use advanced laser scanning adding reverse engineering tools and techniques, Direct Dimensions that inspect and analyze your object or part in a variety of method:

- Compare scan part that adds “nominal” or intended design model.

- Compare a scanned object with 2D drawing dimensions.

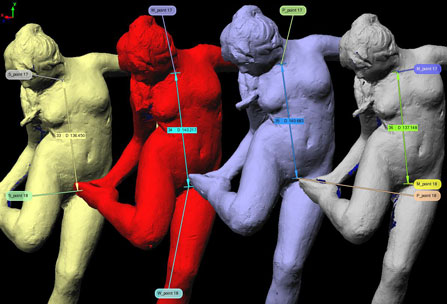

- Compare a scanned with another scanned object.

REPLICATION/REPRODUCTION

The replication offers early and essential uses for a 3D file. It uses 3D printing process, adding digital file that creates physical part. It adds laser scanned with reverse engineered part. It uses virtually limitless options for replicating that object. It’s used for:

- Restoration

- Manufacturing Prototypes

- Scaling in either direction

- Making Products

VISUALIZATION/ANIMATION

The app falls into the realm advertising and entertainment adding museum presentations, with adding legal cases, with high-quality training simulations using for 3D model visualizations and animations.

Direct 3Dview to your object used as create online 3D catalogue using proof of concept.

Faces scan a person for animations, mass personalization, avatars, consumer products, adding simulation programs.

- Animation – The recent people scan, objects, and structures uses to create commercials, music videos, films, and video games.

- Rendering – It comes with high-quality 2D renderings that uses 3D models for marketing purposes. The structures and viewpoints offer legal cases that provide eyewitness accounts.

INDUSTRY-SPECIFIC APPLICATIONS

- There are various types of industries that utilise previously listed applications, there adds few 3D model apps along with specific design including:

- Museum Research/Fine Art: investigative scanning for provenance and comparative research

Same 3D Data, Many Different Uses: Repurpose!

Often, with just a little bit of extra work, you can create different, valuable deliverables with the same basic scan data or 3D model. Some examples are:

- A consumer products company has an object scanned so that it can be prototyped. What they might not know is that with a little tweaking of the model they can also gather the measurements needed to create perfectly fitting packaging and also creating photorealistic models for subsequent advertising or a virtual catalogue.

- An aerospace company has a cockpit scanned for human factors analysis. If enough data was initially collected, that same data could be used to help create training simulations.

- A major museum has a sculpture in its collection that is rapidly deteriorating and they want to scan it for documentation. That data could be used to create high-quality mini replications to be sold in the gift shop or for research (possibly comparing it to similar castings by the same artist).

The Sky is the Limit!

The above examples are just a drop in the bucket when it comes to uses for 3D models. If you have a possible application that you think a 3D model would work for, you should just ask your 3D service provider if it can or has been done. If they are anything like us, they will either have already done it (or tried it) or be so intrigued by your application that they are willing to give it a shot! And if you can’t do it yet, check back often; new applications and methods are being invented every day.

The world of 3D imaging, modelling, and engineering continues to grow at such an incredible rate that older applications are always being improved upon and new ones are always being dreamed up.